Private Label Eyewear Mastery: 11 Premium Branding Techniques

As China’s premier eyewear manufacturer, Wenzhou Pinnacle Eyewear empowers 200+ global brands with precision-crafted private label solutions. Discover how our 11 advanced customization technologies transform frames into powerful brand assets.

Strategic Logo Placement Guide

Maximize brand impact with scientifically positioned markings:

| Location | Recommended Elements | Visibility |

|---|---|---|

| Outer Temples | Brand name/icon | High |

| Inner Temples | Model/Size/Color codes | Medium |

| Temple Tips | CE/Made in China | Low |

| Lens Corners | Subtle brand mark (sun lens preferred) | High |

| Lens Center/Lower | Color brand mark (demo lens only) | Medium |

Cutting-Edge Branding Technologies

1. Laser Surface Marking

Process: Reveals base material by removing surface layer

Best For: Metal/plastic temples & sun lenses

Advantage: Permanent single/dual-color contrast

2. Deep Laser Engraving

Process: High-power etching with color infill

Best For: Metal frames

Advantage: Tactile 3D effect with custom hues

3. 3D Hot Stamping

Process: Heat-pressed metallic embossing

Best For: Acetate & injection frames

Advantage: Raised gold/silver logos

4. Mold-Integrated Logos

Process: Embeds branding during frame casting

Best For: Metal/injection molds

Advantage: Seamless luxury finish

5. Metal Plate logo

Process: Groove engraving + metal insertion

Best For: Acetate/wood frames

Advantage: Flush-mounted elegance

6. UP Metallic Sticker

Process: Applies gold or silver sticker → epoxy sealing → polishing

Best For: Perfect for acetate frames

Advantage: luxurious, shiny appearance, elegant, upscale look.

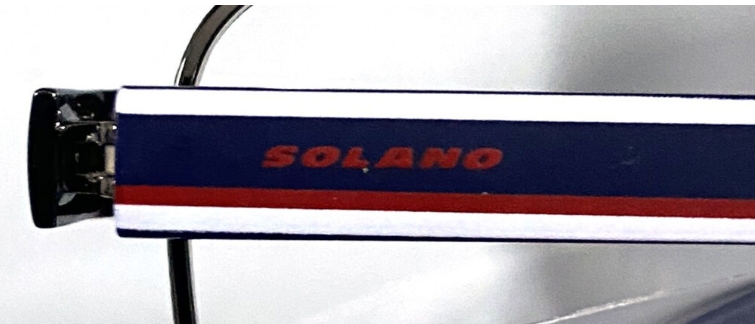

7. Multi-Color Silk Screen Printing

Process: Layer ink through mesh stencils

Best For: Complex graphics on plastic/metal/acetate/demo lens

Advantage: Pantone® color accuracy + gradient effects

Production Tip: ideal for 500+ units

8. Premium Engraved & Color painting

Process: Laser/Etching/Engraving + gold/silver/white resin filling

Best For: Acetate/TR90 frames (inner temples)

Advantage: Tactile luxury finish with 5-year fade resistance

Design Tip: Min. line width 0.3mm for clarity

9. Metal Foil Epoxy Inlay

Process: Groove engraving → metal insert → epoxy sealing → polishing

Best For: Acetate frames (outer temples)

Advantage: Jewelry-grade brilliance with scratch-proof surface

Technical Note: +3 days production vs standard methods

10. Precision Pad Printing

Process: Silicone pad transfers ink from etched plate to 3D surfaces

Best For: Regular used in temples inside

Advantage: 0.1mm resolution for micro-text/logos

Tech Spec: CMYK+Pantone®

Production Tip: ideal for 500+ units

11. Multi-Color Silicone Rubber Logo

Process: Medical-grade silicone into compressible emblems

Best For: Grip enhancement (temples tips inside)

Advantage: 50,000+ compression cycles | IPX7 waterproof

Customization: 3D shapes + Shore 20A-80A hardness

Your Brand Amplification Process

Consultation → 2. Logo Submission → 3. 3D Mockup → 4. Sample Approval → 5. Bulk Production

*(With 48-hour prototype turnaround)*

Why Global Brands Choose Us

1000+ Frame Styles with 100+ customization options

Pantone® Color Matching accuracy

365-Day scratch resistance guarantee

ANSI/ISO certified quality control

40% Faster production than industry average

“From initial sketch to final shipment, we transform brand visions into wearable identity”